Common problem

Common problem

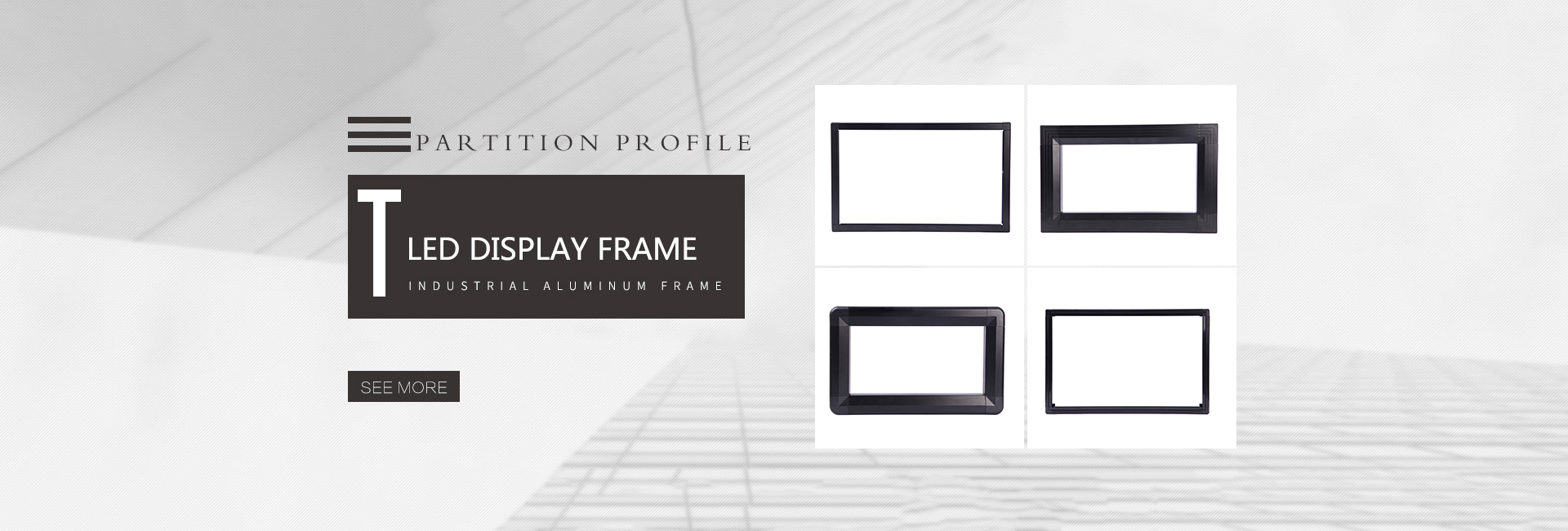

Do you know the production process of LED frame aluminum profile?

LED frame aluminum profile molding is a material used to make our LED frame,usually used for LED display.Today,Xiaobian will tell you about the production process of LED frame aluminum profile.

1.Ingredients:according to the specific alloy brand to be produced,calculate the added amount of heavy alloy components,and reasonably match with various raw materials

2.Smelting:add the prepared raw materials into the smelting furnace according to the process requirements for melting,and remove the impurities and gases in the melt through degassing and slag removal refining methods

3.Casting:the molten aluminum is cooled and cast into round bars of various specifications under certain casting conditions through deep well casting system

4.Extrusion:extrusion is the processing technology of aluminum profile forming.First,according to the profile product cross-section design,the mold is manufactured,and the heated round cast bar is extruded from the mold by the extruder.During extrusion,an air-cooled quenching process and its subsequent artificial aging process are also used to complete the heat treatment strengthening.The heat treatment strengthening alloy of different brands has different heat treatment strength

5.Coloring and oxidation:the extruded aluminum alloy profile has poor corrosion resistance on its surface,so it must be treated by anodizing to enhance its corrosion resistance,wear resistance and appearance.

The above is about the production process of LED frame aluminum profile,hoping to help you.Let’s see you next time.